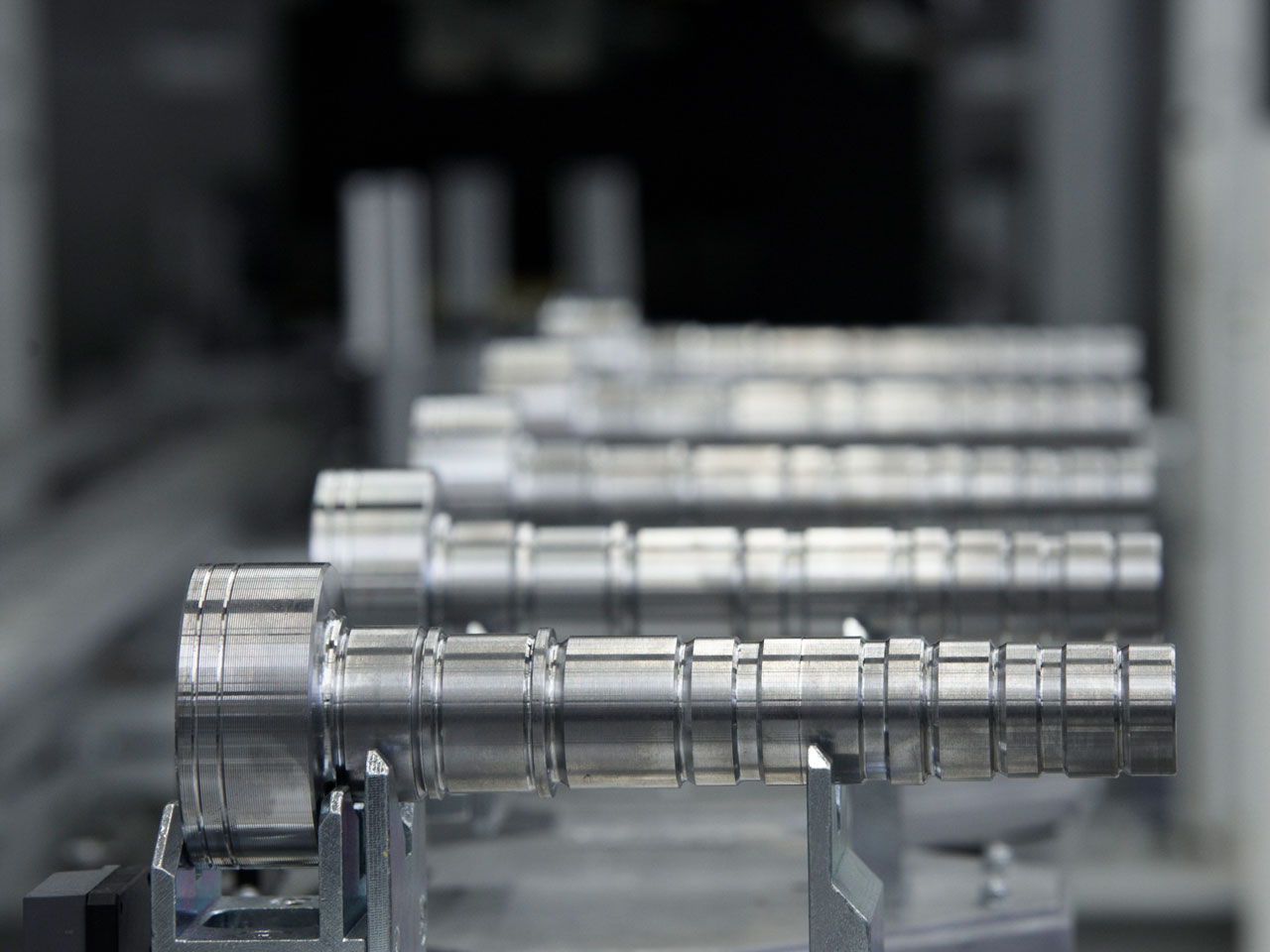

XK 837, XK 851, XK 875

Already more than 15 years ago, when the concept for the XK 8 models was developed, we implement comprehensive energy saving features. A major energy consumption reduction was achieved by replacing hydraulic axis drives with electromechanical components, which also reduced footprint and noise level significantly. With its ergonomically optimized machine guarding, the machine design is compact, while allowing for a maximum profile diameter of 80 mm and workpiece length of 1500 mm.

XK 8xx – Application range

- Passenger car drive shafts

- Passenger car axle shafts

- Efficient production of small batches

Highlights

- State-of-the-art cold forming technology with process control

- All movements are performed by numerically controlled axes

- Variation of workpiece tooth quantity without changing tools

- Vertical feed during rolling

- Rolling speeds can be programmed individually

- Hydraulic free machine – reduced footprint and noise level

- Simplified tool settings

- Increased flexibility