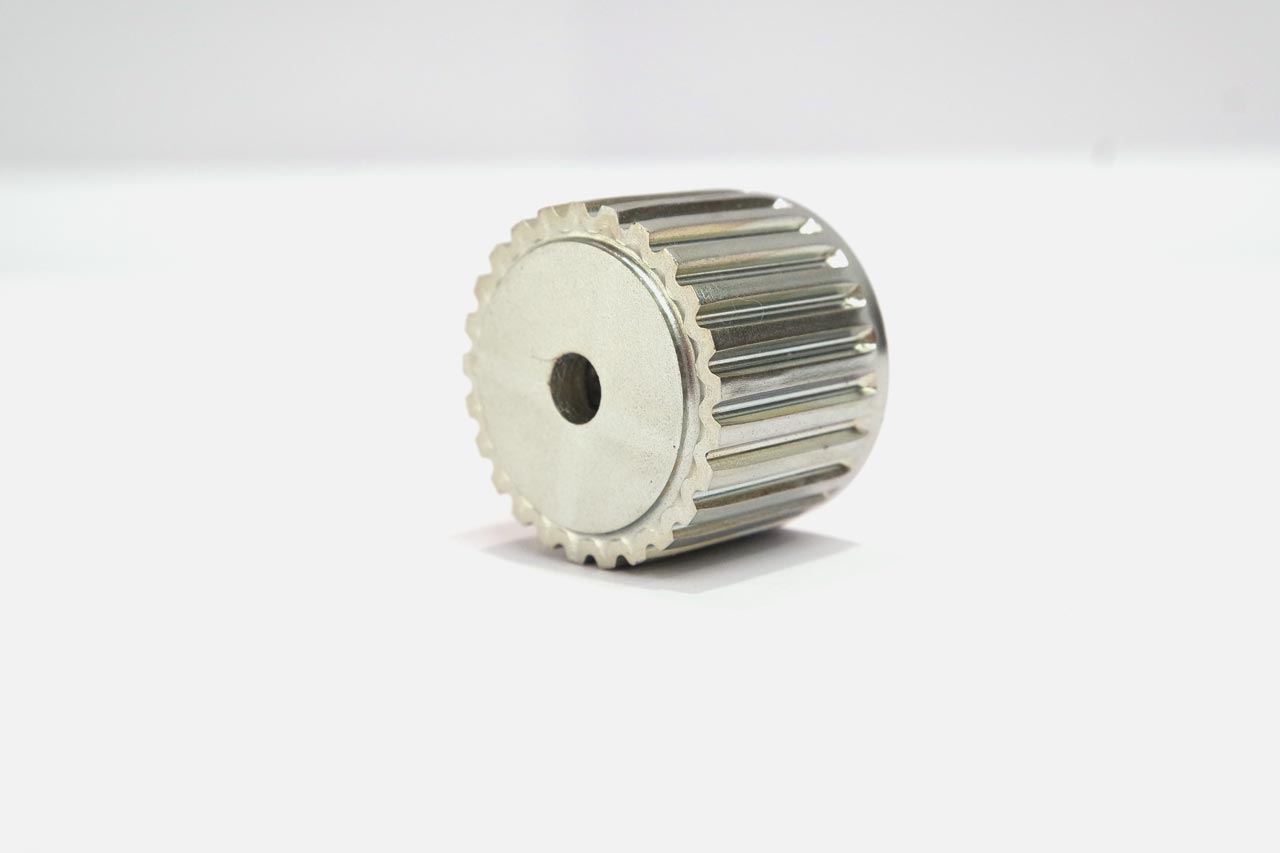

In order to secure splined connections axially, they are often provided with ring grooves into which retaining rings are inserted after assembly. Usually these ring grooves are manufactured after the heat treatment process. This results in investments and process costs for the production of the ring grooves, as well as the removal of secondary burrs in the flanks of the splines.

With our patented technology, ring grooves could already been manufactured in the soft turning process and can be kept free during rolling process.

For this purpose, the axial position of the groove must be exactly determined prior to the rolling process. Subsequently, the workpiece gets positioned accurately using the determined data. This manufacturing strategy ensures process-reliable and chip-free results.